In the modern industrial environment, data is the most valuable asset.

Yet many companies still separate laboratory systems from production systems—both technically and operationally. LIMS (Laboratory Information Management System) handles lab test results, while SCADA (Supervisory Control and Data Acquisition) oversees and controls shop floor production processes.

Both systems hold critical data—but if they are not connected, the strategic value of that data becomes limited.

This is where Labcentric LIMS comes in, offering direct interfacing capabilities with SCADA systems, paving the way for comprehensive and real-time data integration.

Why Should LIMS and SCADA Be Integrated?

In manufacturing environments like foundries, many crucial decisions rely on data from two distinct domains:

-

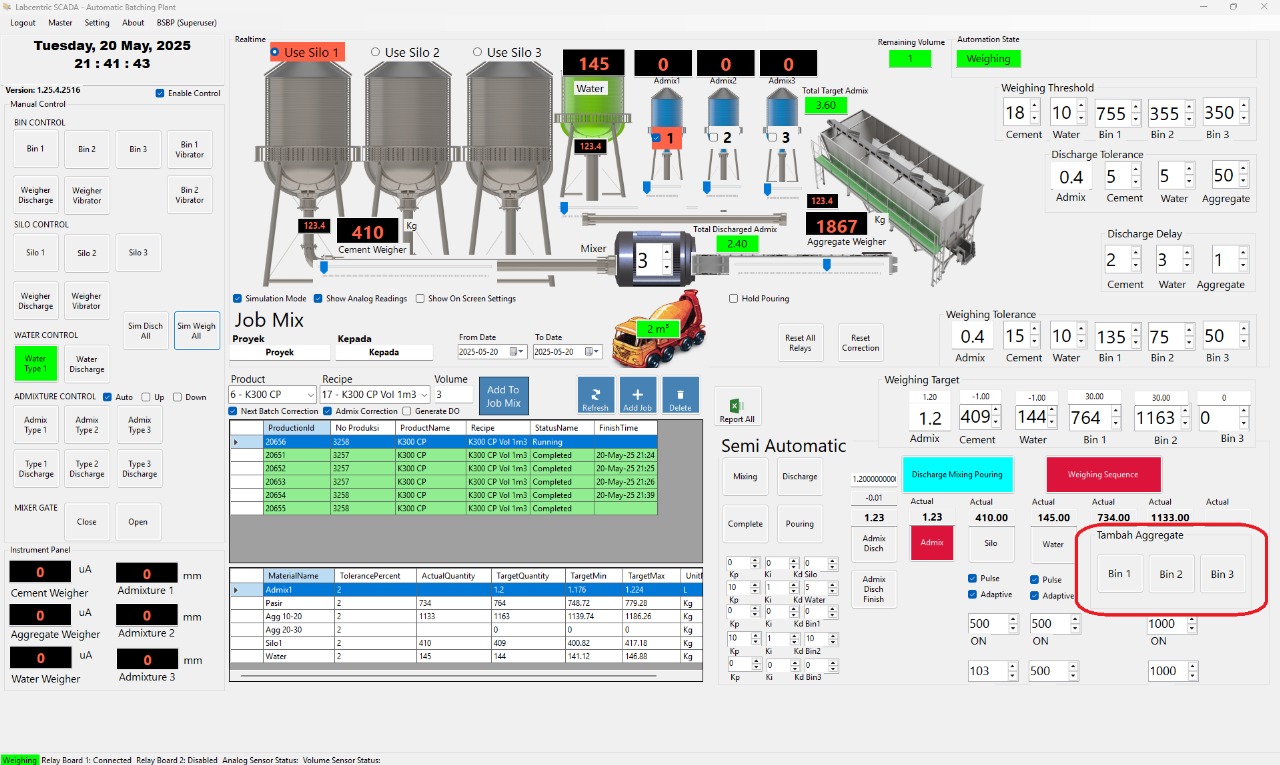

SCADA logs process conditions: furnace temperature, pressure, melting time, energy consumption, etc.

-

LIMS stores analytical results: Si, Fe, Mn, Mg content from OES; sand test results; incoming material CoAs, and more.

Without integration:

-

Furnace operators don’t immediately know whether test results meet the specs.

-

Supervisors can’t correlate furnace temperature variations with metal composition outcomes.

-

Management lacks full visibility of process–product quality correlations.

With integration:

-

Lab and process data are unified in a single information ecosystem.

-

Operational decisions can be made faster and more accurately.

-

Quality issues and bottlenecks can be automatically detected.

Integration Scheme: Labcentric LIMS and SCADA

Labcentric LIMS uses an open, modular architecture, making it compatible with various SCADA systems, such as:

-

Siemens WinCC

-

Wonderware / AVEVA

-

Ignition SCADA

-

GE iFIX

-

Schneider Citect

-

Or even systems based on OPC UA and Modbus TCP

Data That Can Be Integrated:

From SCADA to LIMS:

-

Melting temperature and duration

-

Holding time of molten metal

-

Gas or air flow rates

-

Valve positions, pressure, conveyor speed

-

Trigger status like “sample taken” or “ready for test”

From LIMS to SCADA:

-

Test result status (PASS/FAIL)

-

Metal composition correction suggestions (e.g., “add 0.3% Si”)

-

Target quality parameters (SPC baselines)

-

Alerts if results exceed tolerance limits

Strategic Benefits for Your Company

1. Faster Response to Lab Results

Operators no longer have to wait for Excel sheets or printed lab reports. Analysis results appear directly on SCADA HMIs or MES displays—enabling immediate corrective actions.

2. Unified Timeline of Process and Lab Data

Labcentric LIMS merges process data (temperature, time, pressure) with test results (chemical composition, mechanical properties) into a complete digital footprint for every production lot.

3. More Accurate Analytics and Predictions

With connected datasets, users can perform correlation analysis:

-

Does a 10°C variation impact Mn content?

-

Does scrap lot A tend to cause off-spec results?

This even opens doors to AI-driven prediction models for optimizing mixing formulas or furnace parameters.

4. Seamless Audit and Traceability

When a quality issue or customer audit occurs, you can trace back:

-

Which operator was on shift

-

When the sample was taken

-

What the furnace temperature was

-

What the test results were and what corrective actions were taken

All within one system—no need to dig through multiple files or folders.

Conclusion

In the Industry 4.0 era, data should no longer be siloed across departments. Integrating LIMS and SCADA is a crucial step toward achieving operations that are more efficient, measurable, and auditable.

With Labcentric LIMS, this integration is no longer a massive, complex project—it’s a practical solution that can be implemented modularly and gradually.

Your company will not only have a modern testing system but also place data at the heart of every decision.

Want to know how your current systems can be connected to Labcentric LIMS?

We’re ready to help with technical evaluations and proof-of-concept based on your needs.